-

Home

- About Us

- Products

- Application scenarios

- Download

- News

Classify- Ultrasonic sensor

- Vehicle sensor

Ultrasonic sensor

High quality ultrasonic level meter UM5000市 场 价: ¥0元/个

优 惠 价: ¥0元/个

General Specifications:

- Sensing distance:250…5000mm

- Adjustment range :250…5000mm

- Unusable area :0…250mm

- Standard target plate:100mm×100mm

- Transducer frequency About:75 kHz

- Response delay About :125ms

- Price: 50+ PCS, USD98.5/PC

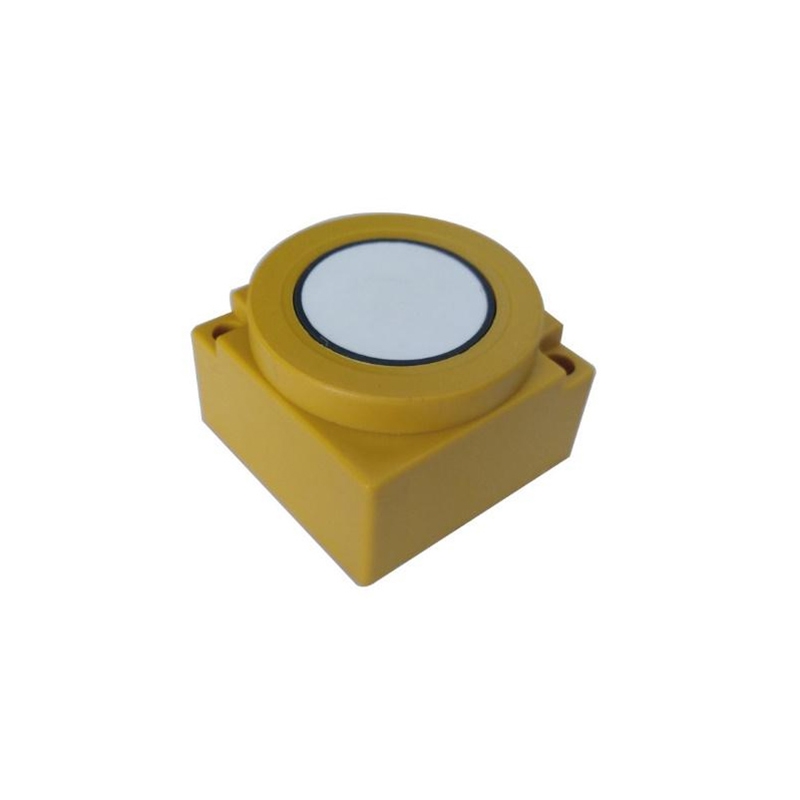

High quality ultrasonic level meter UM5000

I.Product Features

The UM5000 integrated ultrasonic level gauge is an intelligent non-contact level measuring instrument. The product is small size, low power consumption, gain control, temperature compensation, and adopts advanced detection and calculation technology to improve the measurement accuracy of the instrument. It has a suppression function for interference signals to ensure the authenticity of the measurement results. The product can be widely used for measuring the liquid level of various liquids and the height of solid materials, as well as for measuring distance.

II. Application

Liquid level measurement

Container water level monitoring

Material level/height

III: Parameters

Technical data

General Specifications

Sensing distance

250…5000mm

Adjustment range

250…5000mm

Unusable area

0…250mm

Standard target plate

100mm×100mm

Transducer frequency About

75 kHz

Response delay About

125ms

Indicators/Operating means

LED yellow

solid: NO LED

flash:LED red

flashing:

Electrical specifications

Operating voltage UB

9…24VDC ripple10%ss

No-load supply current

≤20mA

Output

Output type

1 analogue output 4---20mA (0-10V, RS485 optional)

Resolution

Deviation of the characteristic

curve±1% of full-scale value

Repeat accuracy

±0.1% of full-scale value

Load impedance

>1k Ohm

Maximum switching current

Temperature influence

±1.5% of full-scale value

Ambient conditions

Ambient temperature

-25…70℃

Storage temperature

-40…85℃

Mechanical specifications

Protection grade

IP68

Connection

PVC cable,4-PIN

Material

Housing

PBT OR FRP

Transducer

epoxy resin/hollow glass sphere

mixture; Polyurethane foamWeight

150g

Compliance with standards and Directives

Standard conformity

EN 60947-5-2:2007

IV. Wire connection

V: Adjusting the evaluation limits

The ultrasonic sensor features an analogue output with two teachable evaluation limits. These are set by applying the supply

voltage -UB or +UB to the TEACH-IN input. The supply voltage must be applied to the TEACH-IN input for at least 1 s.

indicate whether the sensor has recognised the target during the TEACH-IN procedure. The lower evaluation limit A1 is taught

with -UB, A2 with +UB.

Two different output functions can be set:

1. Analogue value increases with rising distance to object (rising ramp)

2. Analogue value falls with rising distance to object (falling ramp)

Evaluation limits may only be specified within the first 5 minutes after

Power on. To modify the evaluation limits later,

the user may specify the desired values only after a new Power On.

TEACH-IN rising ramp (A2 > A1)

- Position object at lower evaluation limit

- TEACH-IN lower limit A1 with - UB

- Position object at upper evaluation limit

- TEACH-IN upper limit A2 with + UB

TEACH-IN falling ramp (A1 > A2):

- Position object at lower evaluation limit

- TEACH-IN lower limit A2 with + UB

- Position object at upper evaluation limit

- TEACH-IN upper limit A1 with - UB

Default setting

A1: unusable area

A2: nominal sensing range

Mode of operation: rising ramp

LED Displays (SMP80 series no led)

Displays in dependence on operating mode

Red LED

Yellow LED

TEACH-IN evaluation limit

Object detected

No object detected

Object uncertain (TEACH-IN invalid)

off

flases

on

flashes

off

off

Normal mode (evaluation range)

off

Fault

on

previous state

Links:

Links:

Service Hotline

+86 13923792185

Website:www.micmetering.com

Address:6th Floor, Block B, Area A, Qinghu Science and Technology Park, Longhua District, Shenzhen, Guangdong Province

Copyright © 2025 MIC Metering (Shenzhen) Limited 粤ICP备2025358196号-1 Cookies Policy-

Service Hotline

Service Hotline

+86 13923792185

-

WeChat

-

TOP

Our Cookie Usage Policy

Our website uses cookies and other similar technologies to distinguish you from other users of our website. This helps us provide you with a good experience when you browse our website and allows us to improve our website. For more information, please refer to our Cookie Policy. - About Us